Signup to get discounted offers

Total scam, this is a MINIATURIZED IMITATION 1/10 the size of a real backpack. See attached pic. Chinese scam. Ordered in US, shipped from some scam place in china. will demand full refund, or will be contacting law enforcement. AVOID THESE SCAMMERS

The best Backpack I have ever owned, Charing port Works and lots of space for my laptop, phone and iPad.

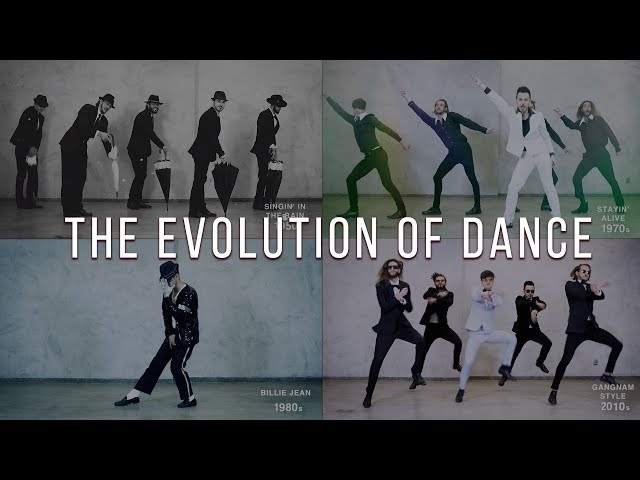

This is How I feel About the Backpack

watch the video below.

I was looking for an affordable, simple, average size backpack for my 6-year-old son. Since he has pretty light need for a backpack at this age I was trying to avoid one of the cutesy character backpacks kids usually go for in hopes this will last at least two years. I have no doubt this backpack will last two years if not longer. It is very well constructed and has a nice amount of padding for the wearers comfort as well. It holds quite a lot and has adjustable straps. We love it. Highly recommend!